Everything is bigger, more sophisticated. Even the whimsy. Especially the whimsy.

Wiseacre Brewing Co.’s massive new state-of-the-art facility in Downtown Memphis is a wondrous, hilarious, deliberate, five-year dream-come-true for company co-founders Davin Bartosch and Kellan Bartosch.

The honey for Tiny Bomb will be brought in in barrels, not buckets. Brewers can cloister themselves away in a low-light, positive-pressure, sensory-deprivation tank to taste beer more precisely. The taproom will feature busts of heroes such as Beavis and Butthead creator Mike Judge. There will be dioramas, a big cuckoo clock, and furniture from the Oak Court Mall food court.

Brandon Herrington

Brandon Herrington

The 2019 groundbreaking ceremony for Wiseacre’s new brewery and taproom Downtown.

It’s a perfect blend of Wiseacre’s eclectic, fun-loving brand — and the company’s dogged dedication to quality and consistency in its products. The Bartosch brothers take their work seriously, and they take their play seriously. All of that becomes perfectly evident when you visit the new taproom, especially if you take a brewhouse tour.

Everything in the taproom and the expansive outdoor patio — from the tubular concrete bar that will be “written about in trade pubs” to every carefully selected tree in the biergarten — was designed to make visitors feel at home. Everything in the brewery — from the laboratory to the canning line — was designed to make the best beer possible, in the specific way Wiseacre wants to do it.

Wiseacre Brewing Co.

Wiseacre Brewing Co.

Brothers and Wiseacre co-founders Davin Bartosch (left) and Kellan Bartosch (right).

Kellan and Davin are deep in a discussion with landscape architects when I arrive for a visit. The brewery grounds are abuzz with workers washing windows and polishing up a thousand finishing touches. The brewhouse hums quietly, churning an ocean of beer somewhere inside. Outside the brewhouse, a long silver pipe merrily chugs little puffs of white smoke, like someone has just picked a pope.

For nearly an hour-long tour, Kellan and Davin became Willy Wonka and I was a better-behaved Charlie Bucket (I did not steal Fizzy Lifting Drink). The two knew every knob, hose, beam, tank, pump, pipe, and pipe fitting in the building, which seemed to get bigger as we went from room to room.

They can show you around better than I can. So, how about I let them? Come on and ride shotgun with me on my tour through Wiseacre’s new space …

Wiseacre Brewing Co.

Wiseacre Brewing Co.

Bubble windows amp up a taproom mural and give clear views into the shiny, new brew house.

The entire north wall of the taproom is a green mural, a work of art that could easily be at home on a Wiseacre can. The wall has human-sized bubble windows, through which you can spy the laboratory-white walls and towering brewhouse tanks, gleaming silver in the light.

Wiseacre Brewing Co.

Wiseacre Brewing Co.

The taproom bar under construction.

The massive, curving concrete bar seems a good fit for the taproom, which seems big enough for a Grizzlies practice. Windows go all the way to the floor. Glass garage doors will roll up when the weather’s good. The room is bathed in sunlight. If you didn’t know what you were looking at, the space could be the showroom floor for the most elegant monster truck dealership in the world.

Memphis Flyer: When did y’all first think of putting up a new building?

Kellan Bartosch: I think it was 2014. We thought we were going to be [at the Broad Avenue location] for 10 years. We bought the tanks in 2013. We expanded two more times in there. So we reached capacity in January 2016.

But even before that we had plans for how we were going to make more beer — here’s where we’re going to go; here’s how we’re going to grow. We were looking for a place for years. We thought it was unfortunate, honestly, that it became a public thing with the [Mid-South] Coliseum. We weren’t interested in that and we kind of became a public story. We didn’t want that.

Davin Bartosch: Retrofitting buildings — which was what we did on Broad — it’s really not good for brewing. The best breweries are all designed and built [for brewing] because [the building] should function as a brewery. There’s just so much plumbing and electrical and things that people don’t put in normal buildings.

KB: We had a process engineer who actually looked at the Coliseum. He was like, “Well, can you just tear it down and build the brewery there?” He thought we were in love with land, and that was his advice. There were a couple of instances where we were really close to a lease, which we didn’t want. We knew we wanted to build a brewery.

I drove by this [piece of land] one day, just almost by chance. Our distributor is right over there, and there was a ”for-sale-by-owner” sign in the ground. I called, and a couple of weeks later, we had [a letter of intent to buy the property].

The guy was in a position where he had to sell it. He’d owned it for 30 years. This has been empty my entire life. If you drove by this anytime in the past, it was just bleak. There was nothing here.

But we’re two blocks from Central BBQ and two blocks from the National Civil Rights Museum. We’re three blocks from South Main. We’re close to the Central Station hotel, near the Arrive Hotel, and FedEx is redoing the Gibson.

So, what was the guiding idea here?

KB: We really want it to be … I don’t know if this is a fair analogy, but like the second album. A lot of times bands have been criticized when they do something different. People really liked the first thing, but now we want to do something different.

Well, you know, we’ve changed. People change. We still want it to feel like it’s us but we didn’t want to be the same thing as on Broad. So, there’s not going to be the posters that we have on Broad, for example.

Artist Rachel Briggs has designed some art installations. There’s going to be this … we’re calling the “cat fight cloud.” It’ll be above the taps. Outside there’s going to be some three-dimensional art installed. On this entire wall, there’s going to be a cuckoo clock and it’s going to be really fun.

There’s gonna be busts outside of a lot of our heroes. Some of them are more deserving of hero titles than others. We’re doing William Blake, John Muir, Mike Judge, Alton Brown, Ida B. Wells, Robert Reed Church.

Inside, there’s going to be little dioramas of our beers, shoe-box scenes of Tiny Bomb and so on.

What’s happening over here with this big window?

KB: It’s the serving window, but we don’t even know what we’re doing in here. We were having conversations with people, but there’s nothing to report on that.

We wanted to be able to serve beer outside through that window. When the weather’s nice a lot of people show up and you want to be able to serve them [outside]. But then on, say, most Mondays through Wednesdays, there’s like five people here. So you don’t need to have to have your windows open all the time.

Every brewery has food already. They’re just from food trucks. We wanted to be able to figure out a way to do that on our own. So there’s no finished thought there — yet.

DB: Either way, it’d be cool to have a food identity instead of rotating and having the never-endingness [of food trucks]. It’s kind of going back to basics. Boscos has been doing it for years. So we’re borrowing from Boscos.

KB: You go to these places like [Stone Brewing] or to New Belgium. It was our dream. We wanted to become a great production brewery and have this place that could really put us and Memphis on the map. That’s the thought behind the vision — that this could be a draw and bring people to Memphis.

Over here looks like y’all have tons of taps.

DB: We have 30 taps. We won’t perceive that they’ll be full all the time. We’ll probably double on some stuff that people drink a lot of, like Tiny Bomb. But there may be times we can have all of them on.

Over here, we’ll have some high-top tables and some low-top tables. Davin has been on a personal mission for about a year now to acquire tables and chairs from the Oak Court Mall food court — and he’s done it.

Wait, where did you get them?

DB: Oak Court Mall.

You just went up there and asked, “Are y’all selling?”

DB: And they sold them all.

KB: We’re going to get them sandblasted and powder-coated, and painted different colors.

So why those chairs?

DB: I thought they were cool — like wire but super heavy. It came about because the designers picked out some chairs, and I said, “Those look like the Oak Court Mall chairs.” Then, I just thought, all right, I’m going to see if I can get the Oak Court Mall chairs.

These windows over here look so clean. They look like they’re not even there.

DB: Oh, yeah. They’re not there actually.

Oh, my god. I’m glad you told me because I was looking at it and thought it was amazing. I’m an idiot. … When you were designing this place, did you look at other regional breweries like, say, Sweetwater? Or did you just say, this is what we want?

DB: Well, there’s so much customization that you have to do when you’re going from where we are on Broad to here because you want to keep your processes the same.

I don’t want the beers from here. … I mean, they’re gonna taste somewhat different no matter what because there’s, there’s just too many variables. But you want to try to stay as true to the style and the ways you are making beer. For instance, Tiny Bomb has a bunch of honey in it. That’s not a typical ingredient in beer. So this vessel is built entirely so that we can put honey into Tiny Bomb.

You have to do stuff like this in order to do it at our size. Now, we just fill buckets. Now, I mean, you just can’t fill 15 buckets every time you want to brew a beer.

KB: We get the honey from Jimmy Deaton. He has a symbiotic relationship with the soybean farmers in North Mississippi.

DB: He provides pollination for soybeans and has thousands of hives throughout the city. We basically buy all of his honey at this point. You used to [be able to] get his honey in grocery stores. He’d fill little bears and sell them. But now he’s like, “You’ve made my life incredible. I bring you a drum and then I go back to my job. I’m not [hustling].”

Davin, you’ve always talked about keeping your beers consistent. How is this new place going to help that?

DB: The devil’s in the details. At our other brewery, we have five different people that might be stirring the mash. Everybody stirs differently. Some people stir this way. Some people are stronger than other people. People stir for a longer amount of time. Anyway you look at it, that stirring is changing how you’re breaking down starches in the sugars, both in the method and the actual extraction.

Any time you can take a variable and control it, you can have a much better finished product. A lot of what [the new location] does is allow us to control the variables. I can hit temperatures within a half of a degree here. At Broad, it’s a crapshoot. We’re usually within two or three degrees if we’re lucky.

But if you have a cold snap and your groundwater temperature changes and, then, the temperature of your grain changes … . That’s just too many variables. Here, I’m able to very specifically control what’s happening.

KB: He’s not a control freak at all. He’s just always thinking of the end result. All the tiny details add up to that. We’ve done an amazing job of that on Broad for seven years. This just allows us to do that better.

When Davin says it’s going to be different, no one will notice besides Davin. But even if you don’t consciously realize that, yeah, this tastes better, it’s going to be more drinkable.

We walk past the massive tanks and platform where Tiny Bomb is made. We push through gray double-doors into the humming, hissing heart of the brewhouse.

DB: This is the boiler room. It’s actually not a boiler. It’s a steam generator. There’s only five gallons of water in this whole thing. It’s immediately blasting off steam. So, it’s way, way, way more energy efficient than our previous brewery. There, we make hot water into steam 55 gallons at a time. Here, it’s steam on demand, basically. Way less electricity. Way less gas. Way less water.

We walk to another room, this one filled with large grain hoppers, a mill, and large, industrial-sized bags (called super sacks, heh) hanging in racks along the wall.

DB: That’s wheat malt. It’s a big part of Ananda.

All the silos are on the other side of this wall. You can see the two pipes that come into the room from the outside. So the malt is coming in this way.

KB: The silos are for base malts. The super sacks are for more widely used specialty malts and we have smaller bags for specialty malts.

DB: This is maybe the biggest difference from our other brewery. We have a two-roller mill. It’s, basically, what everybody has. But the new, four-roller mill allows us to crush grain in a very consistent way and it allows us to not over-crush and still get very good extraction.

When you’re milling malted barley, you need the husk to filter your grain bed. So, the problem with most mills is, in order to get the crush you need to extract the endosperm, you have to destroy your husk.

This is a four-roller mill. It has one step where it’s, basically, shearing the husk off of the endosperm. There’s another where the endosperm is getting crushed. Because the husk is already off, it just slides through the other parts and we end up with a whole husk from the malt but completely crushed and destroyed endosperm.

We’ve already seen [the changes] it is making in the beers we’re making here so far. It’s making an enormous difference.

KB: Just … uh, we’ve said super sack and endosperm in pretty short order. So …

You got to have them. You can’t have an endosperm without a super sack.

We walk up a free-standing flight of silver stairs to a platform, to the top of the enormous silver tanks. Davin invites me to look through a glass porthole to the inside, where a dark, oatmeal-looking, hot mash churns with satisfying efficiency. The mash is an early step in the brewing process where the grains (think malt and barley) make sugar and are readied for fermenting (the part that gets you drunk).

The tanks are from Siemens. A Siemens joke is made.

We move along to another, quieter room. Remember your high school science lab? The chunky countertops, the mysterious devices and sinks in mysterious places? It’s all here.

DB: This our laboratory. We’re not built all the way yet.

We’ve had one for awhile but it’s been very spread out. This will be a dedicated space. We’ll have way more testing supplies than we have on Broad. We’ll be able to keep track of our beer and our specifications a lot more.

We walk to another set of massive tanks used to grow and store yeast. It’s a vital part of brewing. Yeast eats the sugar made by the grains and makes our old pal, alcohol.

Davin calls them “smaller tanks” and laughs at the description. Each tank holds 20 barrels, or about 40 kegs. They’re the size of the first fermenting tanks Wiseacre had at its Broad Avenue site. Now their yeast-handling system is that size.

Wiseacre Brewing Co.

Wiseacre Brewing Co.

Towering tanks will allow Wiseacre to ramp up production.

What will happen over at the Broad Avenue location?

KB: In the past three years, we’ve made 500, 600, or 700 barrels of specialty beers. Our plan is to make around 2,000 barrels of specialty beer. So, we get to make more of the fun stuff. They won’t really grow as a percentage of our business. But we’re going to make a lot more specialty beers on Broad.

DB: A lot of us get into [brewing] for the fun of it, the art aspect. It’s a creative outlet as well as an occupation. So, I think [making more specialty beers] is really important to the future of Wiseacre and the future of our brewers.

What’s a beer you’ve been dying to make?

DB: We’ve been pretty limited in our sour/wild area. You have to be extremely careful and you just can’t do them all the time. So, it’ll be fun to get a little bit deeper into that section.

We also haven’t been able to make any long-tank-time lagers of some sorts. That’s a passion of mine, obviously, with Tiny Bomb being my favorite beer.

Where do y’all get your beer names?

KB: They come from all over. I have a running list. If I hear a word I like, I jot it down. More often than not, they come from someone saying a word and I’m like … yeah, that.

There are times we overthink it and it takes forever. But it’s something that we care about a lot. We try to stay away from drug innuendos or sexual innuendos. So, there’s things we don’t want to do. We want to be a little obscure. There’s a desire for someone to want to look up [a beer name] and see what it means. A lot of it comes from our dad. If we had a question growing up, he was always like, “Let’s go get the encyclopedia and look it up.”

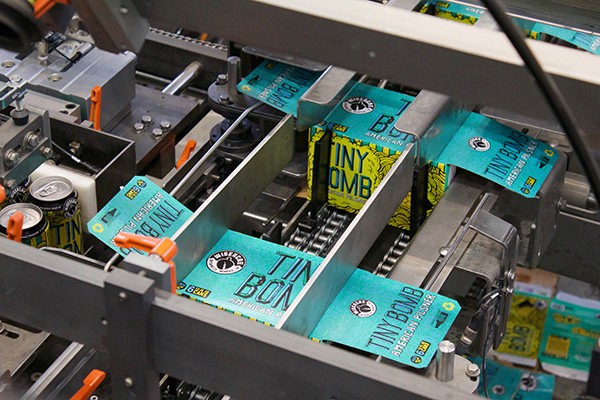

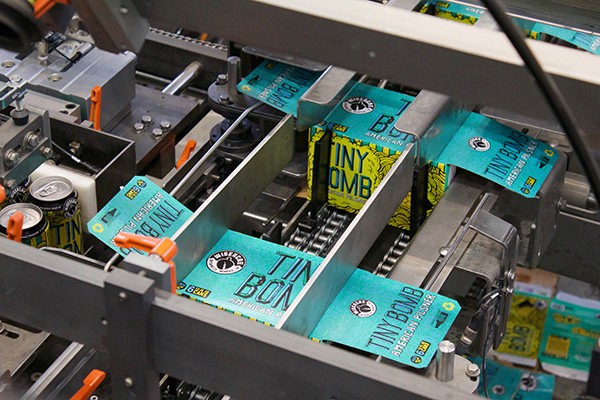

We walk over to an enormous piece of equipment with a sort of Rube-Goldberg feel to it. Huge stacks of empty, topless cans line up with a maze of conveyor belts leading to a domed, circular glass-and-steel device that would fit right into a sci-fi laboratory. It’s Wiseacre’s new canning line. It’s from Krones. Davin says it’s the same company that makes canning lines for Coke and Budweiser and is “the best canning equipment in the world.”

Wiseacre Brewing Co.

Wiseacre Brewing Co.

All Wiseacre six packs are now packaged in cardboard boxes, instead of plastic ring holders.

At Broad Avenue, Wiseacre’s canning line can fill around 70 to 80 cans per minute. The new line will fill 265 per minute, and with less waste.

Just past the canning line, we walk into the cooler — a cold, refreshing paradise for any Wiseacre fan. Pallets of packaged cans — Tiny Bomb, Ananda, Beach Within Reach, and more — are stacked over our heads. It’s the end of the beer rainbow. It’s Willy Wonka’s Chocolate Room, only it’s drinkable.

And another revelation: 16-ounce cans packaged in a case (a 24-pack).

Whoa. When did y’all start doing that?

KB: Last week. It’s pretty exciting. We’ve got Regular, Tiny Bomb, and Memphis Sands in 16-ounce cans.

Why go 16-ounce?

KB: It’s new opportunities. It hasn’t been a big part of the Memphis beer world yet. But in other places, music venues prefer them. Bigger sports arenas prefer them.

There’s a lot of convenience stores, especially in East Tennessee, that are changing that way. I was in Colorado and went into a convenience store. The whole [beer section] was just 16-ounce cans. There’s just a lot of consumers who prefer that. So, this is just a new way to get beer to people and for them to choose us.

Outside the cooler and through an unassuming door holds another Wiseacre innovation. It’s a narrow room. Low light falls on a narrow bar that’s sectioned by little wooden walls, like a bank of payphone stalls from some bygone airport. At each stall is a curious, tiny door that opens from another room.

DB: This is a sensory room, where we can have people scheduled to try beers at different times. [The doors] go through to the laboratory. Someone in there will put out samples, when you’re scheduled, and you can taste and write notes.

There’s only positive airflow into this room. So, there won’t be any smells from the outside.

KB: You said, “smells.”

DB: Smells. Heh. Everybody here will be scheduled to taste beer. Everybody always makes fun of it, and they’re like, “Hey, I want to be a beer taster.” Well, it’s super-important that we know what our own beer tastes like.

Back outside, the small army of workers is still buzzing around, cleaning, putting on finishing touches. We stop at a low wall overlooking a massive courtyard. Concrete paths vein through a number of different patio scenes, from smaller gathering spots to a wide-open beer garden with a stage.

If it wasn’t obvious before, Kellan and Davin really have planned every aspect of the massive, new Wiseacre facility. It becomes even more plain when Kellan talks about the trees.

KB: These are Japanese Coral Bark Maples. The bark is kind of red and the leaves turn really cool colors. These are chestnut trees over here, which Davin wanted. They’re very common in German biergartens because they get wide and provide a lot of shade.

That’s a willow, which is kind of a fun one. That’s an October Glory Maple back in the back, which are just beautiful in the fall. That’s a Smoke Tree. That’s an Italian Cypress. These are Blue Atlas Cedars. They get kind of twisty. The city requires us to have street trees. So, these are all Ginkgos along the way there. The way it was planned, there will be a lot of different colors in different times of the year.

We turn around and Kellan gestures to what is now a blank wall.

KB: On that whole wall, there will be a three-dimensional art [installation]. There’s also art that goes up behind the screens, and at night when it gets lit up, it’s going to look amazing. There’s an acorn that goes up there but no wording. But down on this concrete curve it’ll say “Wiseacre Brewing Company.”

DB: Because we don’t want people to keep guessing what this might be.

KB: On the northwest corner, there’s going to be a big eyeball, like an all-seeing eye, that says “Wiseacre.”

After more than an hour, I let Kellan and Davin get back to work, back to readying everything for the eventual full open of their spectacular new brewery. And when will that happen? Nothing is certain in these days of “phased reopenings” and “surges” and “flattened curves,” but this summer is the hoped-for target. When it opens, visit the new Wiseacre at 398 S. B.B. King Blvd.

Brandon Herrington

Brandon Herrington  Wiseacre Brewing Co.

Wiseacre Brewing Co.  Wiseacre Brewing Co.

Wiseacre Brewing Co.  Wiseacre Brewing Co.

Wiseacre Brewing Co.  Wiseacre Brewing Co.

Wiseacre Brewing Co.  Wiseacre Brewing Co.

Wiseacre Brewing Co.  Richard Murff

Richard Murff